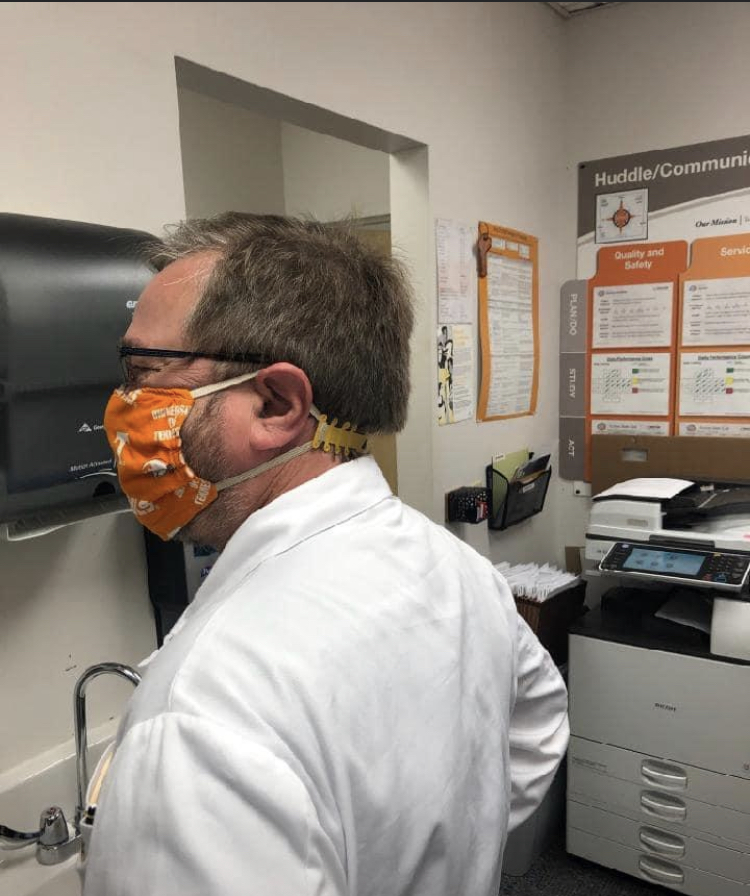

Special tensioners make mask-wearing more comfortable for those on the front lines of the COVID-19 battle

By Emily Booker

In a time of pandemic, even a small piece of plastic can be a big act of charity.

The Knoxville Catholic High School robotics team, the Robotichauns, found a way to use its knowledge of technology and engineering to provide a bit of comfort for medical workers on the front lines of fighting COVID-19.

Doug Parris, who is the team mentor for the KCHS Robotichauns, had heard stories of the discomfort from the long-term wear of masks. Mask strings rub against medical workers’ ears or slip when they adjust their glasses. Tensioners, small plastic strips, can hook the mask in the back, keeping it taut without straining the ears.

“I have friends that work in the medical field. When I learned about the mask tensioners, I asked my friends if they would be helpful. The reply was overwhelming in favor of us providing them,” he said.

Tony Spezia, a senior at KCHS planning to study mechanical engineering at the University of Tennessee in the fall, took the lead in using the Robotichauns’ 3D printer to produce tensioners.

“We started printing the tensioners when we saw that some doctors and nurses in the area were noting the discomfort that wearing a mask all day caused, especially around the ears,” he said.

He explained that the process starts with a 3D model and inputting it into the “slicer,” which writes instructions for the printer. The printer replicates the tensioner. The Robotichauns are using acrylonitrile butadiene styrene (ABS), a common thermoplastic polymer, because of its strength and durability.

“Before this project, I had been printing parts for the robotics team throughout our competition season, so I was familiar with the process,” Tony said.

Using an open source file, they were able to produce a trial run of 60 tensioners that they delivered to East Tennessee Children’s Hospital and the UT Cancer Institute.

As news of the project got out, requests started to come in. By the end of April, they had made and donated more than 500 tensioners to those on the front lines across the country.

With a little adaptation of the source file, they were able to print the letters “KCHS” and numbers “2393” (their robotics team number) on the tensioners, so people all over the country can know who made them. They also were able to adapt the tensioner to have an extra rung to better fit smaller heads.

“We have gotten feedback from medical workers that they have been working great and that their ears have been much more comfortable,” Tony said.

Mr. Parris concurred.

“Doctors and nurses with hearing aids and glasses love them, and they do not have to keep adjusting the masks or their glasses. Nurses with ears bleeding from wearing the masks all day have seen great relief from wearing them. [The tensioners] fit all the different masks being designed and used. We also hear they are easy to sanitize,” he said.

The robotics team at KCHS competes annually in an organization called FIRST (For Inspiration and Recognition of Science and Technology). Teams are given a challenge and then build and program robots to complete that challenge. The challenges enhance not just engineering and math skills but problem solving and self-confidence.

“Normally this time of year we would be competing in regional competitions,” Mr. Parris said several weeks ago. “We would also be working on improvements to our robot and teaching the younger members of our team.”

But with school closed and competitions canceled, Mr. Parris was glad to see students still working hard and developing their skills to help others.

Robotics teams across the country have answered the call to help during the pandemic.

And while the 3D printed tensioners are only small pieces of plastic, they make a big difference to the medical professionals and front-line workers using them.

“I think it is a great way to teach kids about community and societal responsibility,” Mr. Parris said. “One of the great things about FIRST robotics is their push to teach kids about helping those in need.

“Tony, who has been in our program since his freshman year, is a great example. His Catholic faith has taught him that he has God-given gifts, and his way to honor God is to use those gifts to better those in need.”